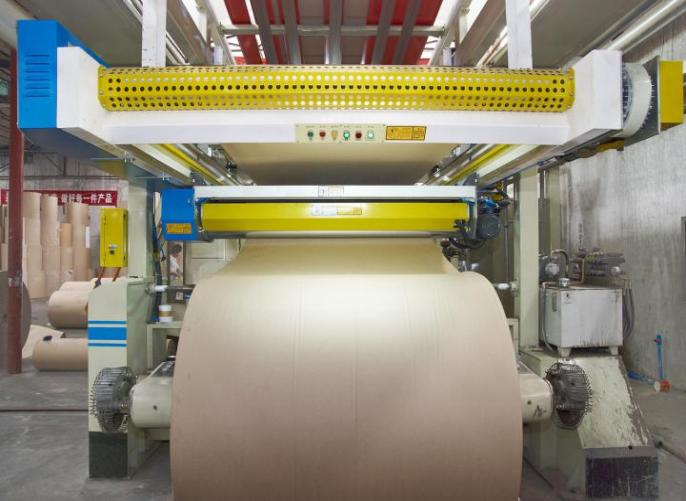

Application range:

1) Suitable for base paper/from 50g to 500g/m2.

2) Has the ability to splicing/ rewinding paper with low gram...

Application range:

1) Suitable for base paper/from 50g to 500g/m2.

2) Has the ability to splicing/ rewinding paper with low gram.

Function:

1) Easy to connect with existing production lines.

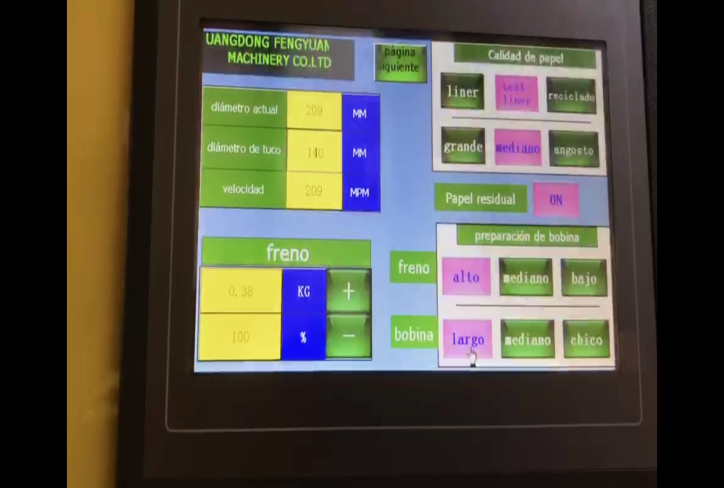

2) Equipped with PLC touch screen, it can diagnose, maintain, control, and monitor the remaining meters and weight through the touch screen

Cooperate with the management of the raw paper warehouse and be able to perform remote communication processing. The operation interface is friendly, and the control panel responds quickly

3) +With a plywood style paper preparation method; Easy to maintain, with sturdy paper preparation and low power consumption. Automatic paper feeder (economy type)

4) Easy to operate and quick to prepare paper

5) Preparing for paper reception is simple and easy

6) Changing the paper roll only takes 1.5 minutes

7) Imported accessories are used for maintenance, with low failure rate and simple maintenance. Automatic paper feeder (economical)

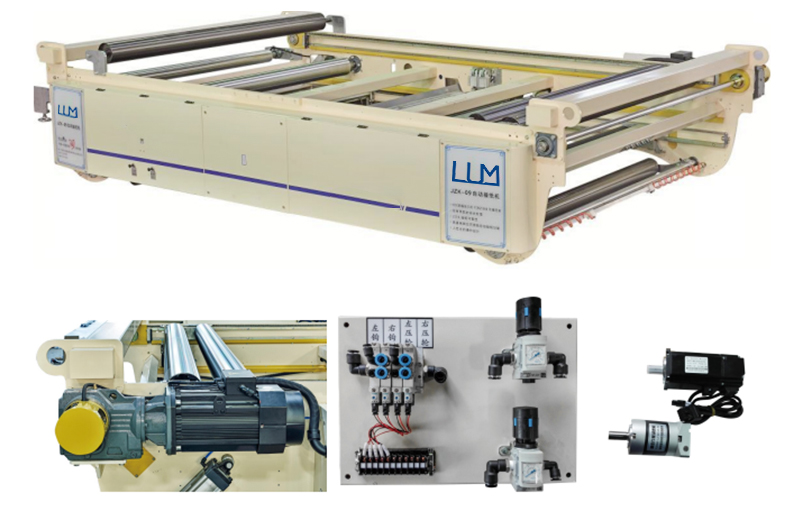

Structure design:

1. The rack is made of high-quality carbon structural steel, and through optimized design, the channel steel has a single end fitting structure.

2. Mitsubishi style single head structure design.

Technical parameter:

1. Design speed: 130m/min (for liner/corrugated paper), 150m/min (for surface paper)

2. Paper connection type: lap joint.

3. Design width: 1400-2550MM, can be customized according to customer needs, with max width of 2550mm.

4. Paper gram range: 50g/㎡~350g/㎡

5. Splicing time of paper receiving reaction time: approximately 1.5 seconds

6. Air source: A dry and clean air source with a minimum pressure of 0.6MPa.

7. Power supply: 380V, 50Hz, 20A/control and control power supply 24V.

Paper splicing speed:

| Paper gram(g/㎡) | Speed of surface paper (m/min) | Speed of liner paper (m/min) |

| 70~90 | 110 | 80 |

| 90~110 | 120 | 90 |

| 110~130 | 130 | 100 |

| ≧130 | 150 | 120 |

Main component and brand:

Electric component:

| Item | Name | Brand |

| 1 | Button/ light | Schneider brand, France |

| 2 | Stitch | Schneider brand, France |

| 3 | Contactor | Schneider brand, France |

| 4 | Intermediate relay | Schneider brand, France |

| 5 | Socket 16A | Schneider brand, France |

| 6 | Transformer BK800 | Schneider brand, France |

| 7 | Electric board | Mingwei, Taiwan |

| 8 | PLC board | Megmeet |

| 9 | PLC/IO extend | Megmeet |

| 10 | Worm gear reducer | Jinxin brand |

| 11 | Motor 0.75KW | Jinxin brand |

| 12 | Magnetic particle clutch | Weizheng, Taiwan |

| 13 | Limit switch | Omron brand, Japan |

Pneumatic parts:

| Item | Name | Brand |

| 1 | SU100X100CA | Airtac brand, Taiwan |

| 2 | SDA50X20-FS564A | Airtac brand, Taiwan |

| 3 | SDA40X30-FS734A | Airtac brand, Taiwan |

| 3 | ACQ40X15-FS566A | Airtac brand, Taiwan |

| 5 | ACP63X50 | Airtac brand, Taiwan |

| 6 | Proportional valve VPPE | Fosto brand, Germany |

| 7 | Solenoid valve | Airtac brand, Taiwan |

| 8 | Five way valve | Airtac brand, Taiwan |

| 9 | Five link base | Airtac brand, Taiwan |

Product details show:

| Auto splicer A | Zero paper-tail design |

|

|

| Auto splicer B | PLC touch screen |

|

|