Main structure:

1. Machine use an integrated color touchscreen human-machine interface system, enabling the belt speeds on either side of the folder to be adjusted, as well as the automatic regulation of the main machine's transmission speed and the conveyor belt of the press machine. Additionally, it features an automated synchronization tracking parameter setting system...

Technical parameters:

| Main Model | LUM-2400 | LUM-2600 |

| Max board size (length + width)x2 (mm) | 2400x1200 | 2600x1200 |

| Min board size (length + width)x2 (mm) | 340 | 340 |

| Max board size (width + height)x2(mm) | 1515 | 1515 |

| Min board size (width + height)x2(mm) | 240 | 240 |

| Height to paper (mm) | 900 | 900 |

| Motor power (kw) | 4.0 | 4.0 |

| Mechanical speed (sheets/min) | 0-70 | 0-70 |

Main structure:

1. Machine use an integrated color touchscreen human-machine interface system, enabling the belt speeds on either side of the folder to be adjusted, as well as the automatic regulation of the main machine's transmission speed and the conveyor belt of the press machine. Additionally, it features an automated synchronization tracking parameter setting system.

2. The device is designed for single-person operation per section of the board, facilitating swift and efficient processing.

3. A high-power stepless speed regulation frequency conversion and high-efficiency powerful motor, capable of achieving speeds of up to 300 meters per minute through synchronized belt power transmission.

4. All the component parts of this device are modularly constructed, facilitating rapid assembly and disassembly, streamlining the process of debugging the box-making product, accessible to novices, intuitive and easy to comprehend.

5. The left and right adhesive cylinders and adhesive spraying systems are specifically tailored to accommodate the distinctive design of the lower lock of the product.

Photometric counting, feasibility for total counting or quantitative counting can be employed to determine the number of kicks required for identification.

Each section of introduction:

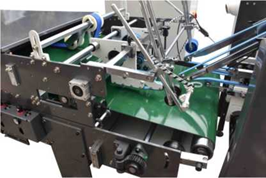

1. Easy to lift the left and right side baffles.

2. The paper feeding belt of the paper feeding section can be independently adjusted to effectively ensure smooth paper feeding.

3. Variable frequency motor, separate speed regulation effectively ensure uniform paper spacing.

1.The cardboard sent to the paper section is corrected by the correction department to make the cardboard go straight.

2. The upper-pressure drive of the correction part can be adjusted up and down to adapt to different paperboard thicknesses and provide stability assurance.

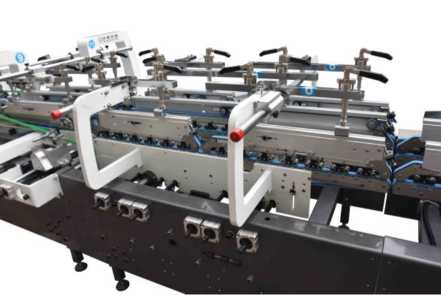

1. Segmented left and right upper belt plate can be based on the product demand expansion adjustment, fast and efficient.

2. Can effectively complete the pre-folding of the 1 and 3 fold lines of the carton,

optimize the effect of final molding.

1. 3 Plate conveyor belt structure, segmented upper belt plate function, can effectively overcome the problems in producing special-shaped box products.

2. The middle and upper belt plate is detachable, as required by the product.

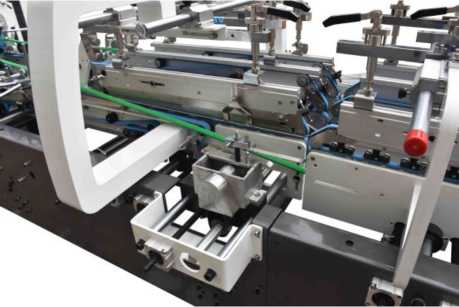

1. Mechanical left and right glue tank.

2. Paste wheel width 3mm, can also be arbitrarily replaced according to the product.

The speed of the left and right outer folding belt can be fine-tuned independently to ensure the forming accuracy.

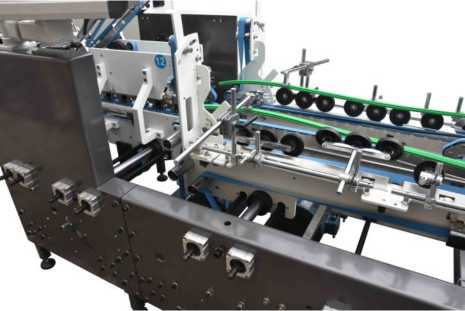

1. Output faster than the folding speed, open the box spacing.

2. The upper and lower belt expansion adjustment is simple and easy to operate.

3. Equipped with high-speed electronic kick counter

1. Set box spacing, belt speed and host speed in automatic mode. When the photoelectric detects the box, the belt moves.

2. In manual mode, the belt moves at a constant speed and is not affected by the speed of the main engine.

3. The pressure part adopts air pressure pressing, the pressure control is more accurate, and the product bonding effect is more guaranteed.

Packaging

Meet long distance kilometers and climate change.

Lead time

After the contract is signed between the buyer and the seller and the deposit is received, the seller begins to arrange production, and the production Lead time is working day.

Transportation

The seller is responsible for domestic transportation to the buyer's designated factory.

Price

Payment

Quality assurance

The Seller warrants that the warranty period of all commodities hereunder shall be 12 months in accordance with the quality and quantity requirements stipulated in the Contract, starting from the completion of installation and commissioning. If any problem occurs within the warranty period, the Seller will send engineers to the customer's site to solve the problem. If necessary, the engineers must arrive at the customer's site within one to three days after the user's notice.

Training, installation

After the equipment arrives at the site, the engineer shall be sent to the buyer's factory for installation and set up. When the buyer prepares the test machine products (paper products and glue used in the test machine), the buyer shall sign the acceptance certificate, and the seller shall train the operator of the buyer, and the buyer shall not arbitrarily replace the personnel. The Buyer shall do its best to assist the Seller in the installation and commissioning period, provide sufficient on-site personnel, power, tools and necessary auxiliary parts, and be responsible for the accommodation of the Seller's installation and commissioning personnel.